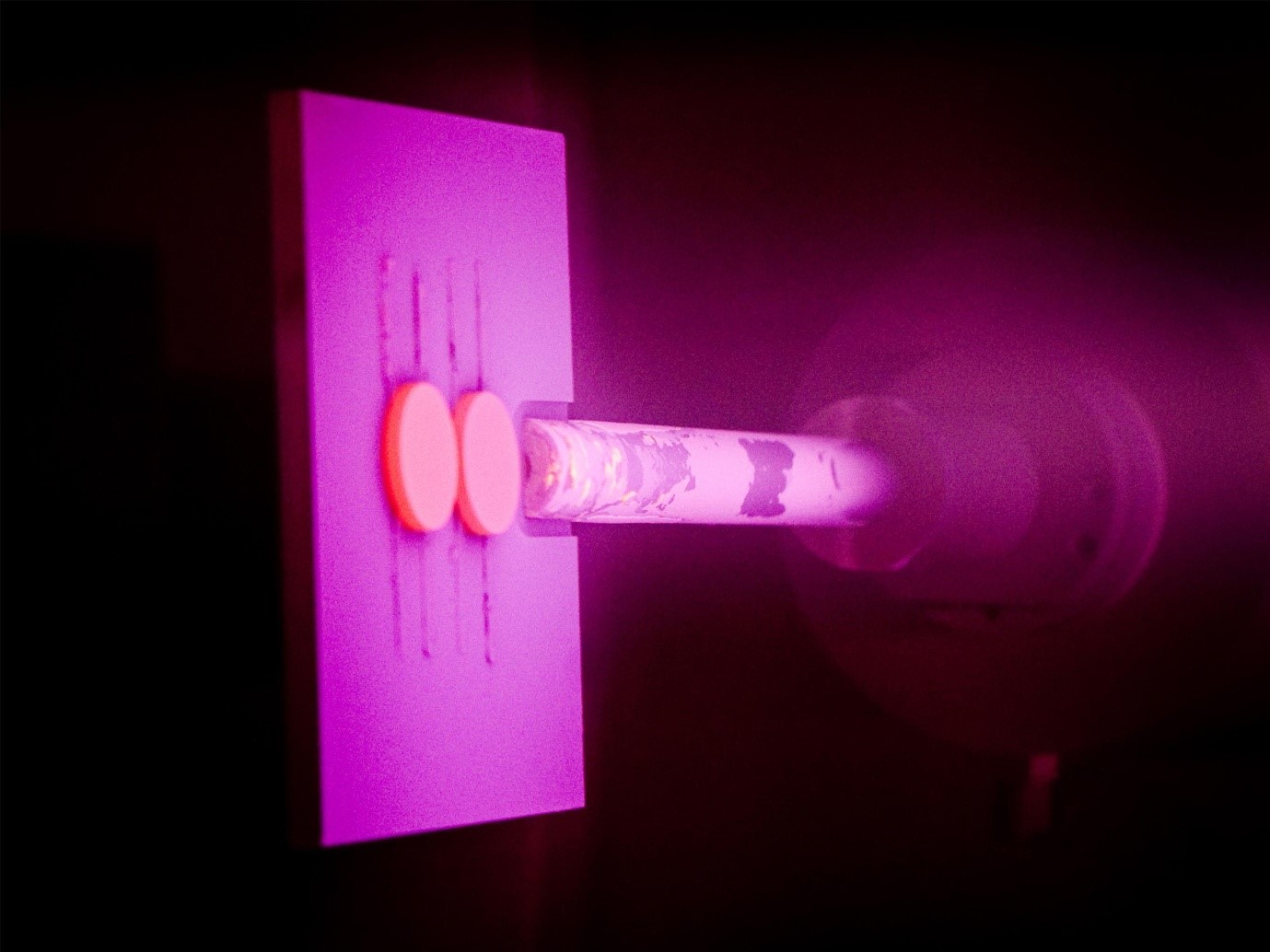

Plasma spraying is a flexible method of providing protection from damage or corrosion for many materials. The flexibility and durability make it a very popular technique which is employed in all sorts of industries.

What’s involved in plasma spraying?

To successfully plasma coat a material or piece of equipment, you must start with the source material in a powder form. To be able to spray the source material, it is injected into a plasma jet which is heated until it becomes ionised. This ionisation is beneficial because it allows materials that have very high melting points to be sprayed.

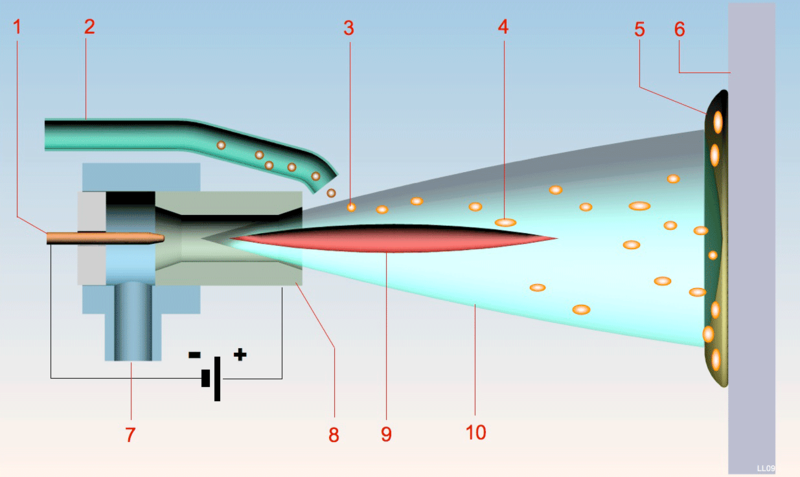

When the powder, for example nickel composites, combines with the plasma gas, it becomes molten and is fired out of the plasma gun to hit the material or object to be coated, where it forms a hard coating once it cools. The plasma gun has a very specific construction involving a copper anode and a tungsten cathode, through which the gas can flow to create the plasma which is then pushed through a construction nozzle. Further description of the equipment and a diagram can be found at https://www.sciencelearn.org.nz/resources/245-plasma-spray-coating.

The pros and cons of plasma spraying

As with all techniques, there are pros and cons with this type of spraying. One of the pros is the wide range of coating materials including metals, such as nickel composites, alloys and ceramics. In addition to the broad range of materials, there are a good range of particle sizes that can be used to get the finish most suitable for the object being coated.

Materials such as plastic, glass, ceramics and metals are coated to maximise their lifespan and durability. Another feature of plasma spraying is the ability to increase the resistance and insulation of the material.

On the down side, plasma coating requires very expensive machinery which is not suitable for every business to own and operate. This is especially true with regards to the replacement of parts for the gun, since the high temperatures involved cause its parts to wear out quickly.

Plasma spraying is an exceptionally versatile technique that results in long lasting, effective coatings on a wide variety of materials. This versatility means that it is used in a very wide range of industries, from engineering to the nuclear industry, household appliances and much more.