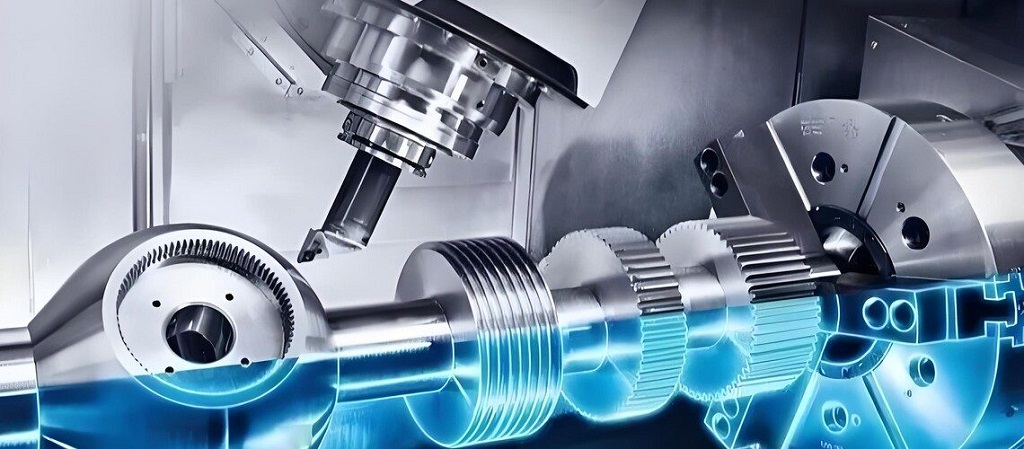

Starting a new business comes with a myriad of challenges, especially when it involves manufacturing. One of the key hurdles is finding a production method that balances cost and quality. Enter CNC machining, a technology that offers startups an affordable and efficient way to bring their products to life. CNC machine companies are paving the way for small businesses to compete with established players by providing accessible and reliable manufacturing solutions.

Streamlining Production Processes

CNC machining simplifies the production process by automating the creation of parts and components. For startups, this means reducing the need for manual labor, which can be both time-consuming and costly. By using computer-controlled machines, companies can produce items with high precision and consistency, ensuring each piece meets the exact specifications required. This automation not only speeds up production but also minimizes the risk of human error, leading to higher-quality products.

Reducing Labor Costs

One of the most significant advantages for startups using CNC machining is the reduction in labor costs. Traditional manufacturing methods often require skilled workers to manually operate machinery and perform quality control checks. CNC machines, however, can be operated by fewer people and require less manual intervention. This reduction in labor not only cuts costs but also allows startups to allocate their resources more efficiently, focusing on other critical aspects of their business, such as marketing and development.

Unmatched Accuracy and Reliability

The precision and consistency offered by CNC machines are unmatched. For startups, this means producing high-quality products that meet strict industry standards. CNC machines operate with computer-controlled accuracy, ensuring that every part is identical to the last. This level of precision is particularly important for industries where even the smallest deviation can lead to significant issues. By maintaining consistent quality, startups can build a strong reputation for reliability and excellence, which is crucial for gaining and retaining customers.

Material Efficiency

Material waste is a common concern in manufacturing, especially for startups working with limited budgets. CNC machining addresses this issue by optimizing material usage. The precision of CNC machines ensures that each cut is made exactly as needed, minimizing excess material and reducing overall waste. This efficiency translates to cost savings, as startups can make the most out of their raw materials and reduce expenses associated with waste management. Moreover, the ability to use a wide range of materials, from metals to plastics, adds to the versatility and cost-effectiveness of CNC machining.

Rapid Prototyping

In the fast-paced world of startups, the ability to quickly develop and test prototypes is invaluable. CNC machining excels in rapid prototyping, allowing businesses to iterate on their designs swiftly. Once a design is finalized, CNC machines can produce prototypes in a fraction of the time it would take using traditional methods. This speed enables startups to bring their products to market faster, respond to customer feedback more effectively, and stay ahead of competitors. The iterative process of prototyping and refining products becomes more manageable and cost-effective with CNC technology.

Scalability

As startups grow, their manufacturing needs evolve. CNC machining offers the scalability required to meet increasing production demands. CNC machines can easily transition from producing small batches of prototypes to larger production runs without sacrificing quality or efficiency. This flexibility allows startups to scale their operations smoothly, adapting to market demands and expanding their product lines as needed. The ability to scale production efficiently ensures that startups can keep up with growth without facing significant disruptions or requiring substantial additional investments in new equipment.

Lower Initial Investment

While the initial investment in CNC technology can seem daunting, it is often more affordable than traditional manufacturing setups. CNC machines are versatile and capable of performing multiple functions, reducing the need for various specialized equipment. This multifunctionality translates to lower capital expenditure for startups. Additionally, the long-term savings achieved through reduced labor costs, material efficiency, and consistent quality make CNC machining a cost-effective choice for new businesses.

Enhancing Innovation

CNC machining fosters innovation by providing startups with the tools to experiment with new designs and materials. The flexibility and precision of CNC machines enable companies to push the boundaries of their creativity, developing unique products that stand out in the market. This capacity for innovation is crucial for startups looking to differentiate themselves from competitors and attract customers with novel offerings. By leveraging CNC technology, startups can transform their innovative ideas into tangible products efficiently and affordably.

CNC machine companies are revolutionizing the way startups approach manufacturing, offering an affordable edge that balances cost, quality, and efficiency. By streamlining production processes, reducing labor costs, and enhancing precision and scalability, CNC machining provides startups with the tools they need to succeed in a competitive market. As technology continues to advance, the benefits of CNC machining for startups will only grow, making it an increasingly essential component of modern manufacturing.