The manufacturing industry has seen many advancements that have propelled society into an era of mass production and convenience. At the heart of this progress lies the plastic injection molding process—a technique that molds our material world in myriad ways. What began as a mechanism for producing simple combs and buttons has evolved into the backbone of complex production across countless applications. With plastic injection molds, industries achieve efficiency, innovation, and precision on a previously unimaginable and unimaginable scale.

A Brief History of Plastic Injection Molding

Plastic injection molding began over a hundred years ago with the advent of celluloid production. This led to the invention of the first injection molding machine by John and Isaiah Hyatt in 1872. Over the years, the process evolved through World War II, and the demand for mass-produced plastic goods significantly boosted the technique. Building on these historic foundations, modern-day injection molding can now leverage computerization—leading to unprecedented precision, repeatability, and scale.

Understanding the Basics of Plastic Injection Molding

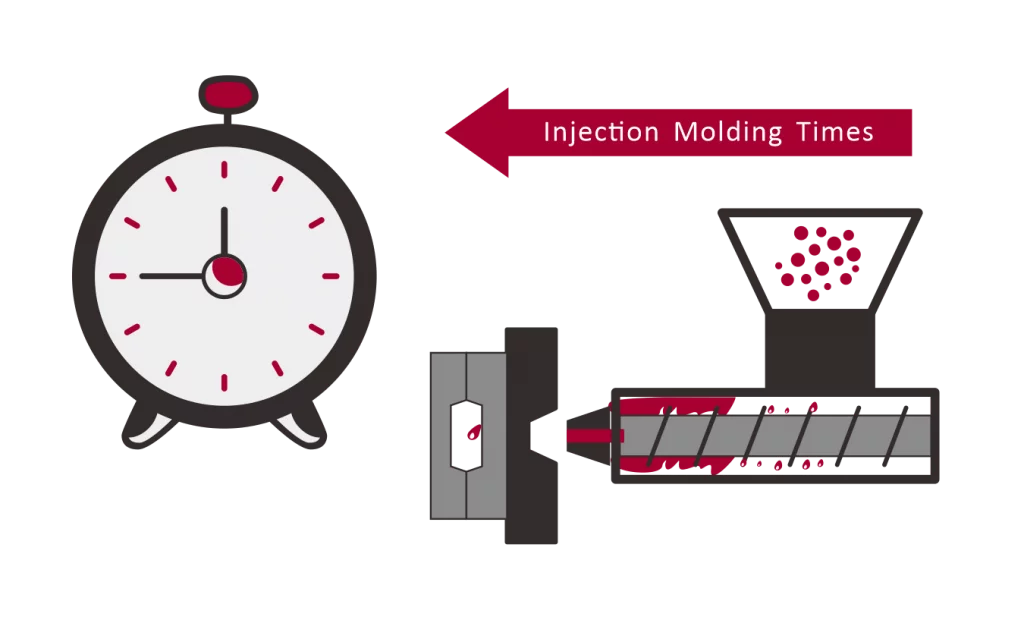

Plastic injection molding is a marvel of modern manufacturing technology. It begins with polymer granules that are melted into a liquid state and then forcibly injected into a meticulously designed mold. As the material cools, it takes on the intricate shape of the mold cavity, resulting in a high-fidelity reproduction of the intended design. Polymers such as polystyrene, polyethylene, and polypropylene are frequently employed for their respective properties that cater to different product demands. The molds, often crafted from steel or aluminum, represent significant investments in the production cycle, but their reusability and durability amortize initial costs effectively over high-volume runs.

The Environmental Perspective of Plastic Injection Molding

Amid growing environmental awareness, plastic injection molding is undergoing significant scrutiny. Critics often cite concerns surrounding non-biodegradable waste and the carbon footprint associated with plastic production. In response, the industry is innovating with recycling programs that extend the life of plastic products and the development of materials such as bio-resins, which offer a more sustainable end-of-life scenario. Energy-efficient machinery and process improvements also reflect the ongoing efforts to minimize the environmental impact while maintaining high productivity levels.

Key Takeaways:

- Plastic injection molding has roots in the 19th century and has advanced significantly.

- The process involves melting polymer granules and injecting them into a precision mold, emphasizing the significance of mold design in product quality.

- Contemporary concerns focus on environmental sustainability, propelling the industry toward innovations in materials and processes.

Applications of Plastic Injection Molding Across Industries

The versatility of plastic injection molding has led to its applications permeating various industries. Medically, the technology has facilitated the production of prosthetic components, surgical tools, and diagnostic devices. These medical-grade components benefit from the process’s ability to produce sterile and highly detailed parts en masse. Likewise, the automotive industry takes advantage of strong, lightweight, and heat-resistant automotive parts made possible by molding. Furthermore, consumer electronics thrive on the method’s capability to produce high-precision, miniaturized components crucial for modern gadgets. Notably, as detailed in a report by Plastics Today, the push for innovative medical solutions has underscored the need for precise plastic injection molding.

The Economics of Plastic Injection Molding

Economic efficiency is a cornerstone of the plastic injection molding industry. Unlike handcrafted or more manual production methods, injection molding thrives on its ability to produce vast quantities of components quickly and consistently, which dilutes fixed costs and diminishes unit expenses. Scale plays a pivotal role; as production volumes increase, the cost-return ratio becomes increasingly favorable, often making a difference in highly competitive markets. This is especially crucial in the current global economy, where efficiency and cost control are fundamental to maintaining market leadership.

Overcoming Challenges in Plastic Injection Molding

Despite its many advantages, plastic injection molding is challenging. Issues such as warp, sink marks, and incomplete cavities can mar production output, necessitating rigorous quality control measures. Moreover, labor is challenging—skilled technicians are essential for operations, maintenance, and molding optimization. As the process becomes increasingly technological, so does the need for advanced training in computational fluid dynamics and 3D CAD design, which are integral to realizing the full potential of plastic injection molding.

The Future of Plastic Injection Molding

The trajectory of plastic injection molding is pointed toward more incredible innovation and sustainability. Technological advancements such as 3D printing and AI-driven process optimization promise enhanced capabilities and waste reduction. As this Manufacturing Tomorrow article outlines, industry analysts forecast significant leaps in materials science and automation that could redefine manufacturing standards. Moreover, legislative pressures and societal demands will likely foster technologies for cleaner, eco-friendly plastic production.

Choosing the Right Injection Molding Partner

The choice of an injection molding partner is critical to project success. Essential factors for consideration include the vendor’s experience, expertise, technology, and track record in delivering high-quality products within the desired timelines. Moreover, partners adhering to industry standards and certifications assure commitment to quality and continuous improvement—critical aspects for any long-term industrial collaboration.

Conclusion: The Integral Role of Plastic Injection Molding in Modern Manufacturing

In summary, plastic injection molding is a testament to human ingenuity in manufacturing. It balances meeting economic objectives and the surge for innovative, quality products. As industries forge into a new era marked by rapid technological change and environmental consciousness, plastic injection molding remains foundational, facilitating a future where adaptability and sustainability coexist with industrial progress.