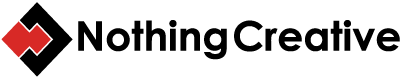

We’ve all heard of galvanized steel, but what does galvanization mean? Well, it’s the process of taking normal steel or iron and applying a coat of zinc around it for added protection. This process is done to prevent early corrosion and rust forming on the metal. Many people prefer using galvanized steel in their work to construct or repair structures because it of its low maintenance, cost and protection from rusting.

Steel is prone to atmospheric conditions and over time will start to corrode and rust. How much rust occurs depends on the environment in which the steel is located. Rust is iron oxide, formed with a reddish-brown colour and is caused by the reaction with iron and oxygen where this is moisture or water present, such as rain. Without the protection from galvanization, this can cause problems for outdoor structures in particular.

There are other forms of protection that can be applied to steel, such as a plastic or paint coating. However, there are disadvantages to using these methods. Over time, when the structure becomes damaged, the coating can chip away, leaving it vulnerable to the elements and prone to further rusting. Therefore, these methods are non-permanent and not as reliable, requiring ongoing maintenance.

An efficient method for protecting steel products against rust and corrosion is the process of hot-dip galvanization. This process involves all surfaces of the steel being dipped into a molten zinc and completely covered. For your galvanized steel parts, like a Spiral Duct, be sure to visit Dust Spares.

The reason zinc is used in this process is because it has a very slow corrosion time. This provides the object with an extended life against corrosion as the zinc coating protects the steel underneath. In scientific terms, zinc provides cathodic protection thanks to the alloying to the iron or steel by the zinc. Any tiny areas of the base metal that might be exposed will still be protected from rusting. No re-covering is required, making maintenance much easier. As long as the zinc layer remains, the protection will last.

Where you place galvanized steel does need some consideration. Zinc can be corroded by certain materials. Extra care will be needed if the galvanized steel will come into contact with brass or copper. Especially in moist environments, copper and brass can cause fast corrosion of the zinc layer. Any running water, for example, coming from a copper or brass object could contain sufficient dissolved copper to cause quick corrosion on zinc.

Galvanized steel remains a hugely popular choice in industry, the main reasons being:

- It is cheaper to use than stainless steel

- It requires the least maintenance

- It lasts a long time

- The life of the coating and its performance can be relied on

- It offers incredible resistance to damage from mechanics

- Small exposed areas of steel remain protected

- No other coating method is as effective

- There is no requirement for preparation of the surface, painting or regular inspection